Curtain wall aluminum profiles manufacturer

- Over 31 years of experience

- China's leading brand

- One-stop purchasing

- 24-hour exclusive service

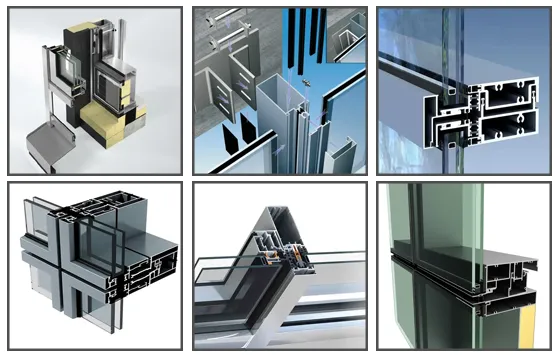

Curtain wall extruded aluminum profile

Xingda has a professional R&D team with more than 20 years of OEM and ODM experience, and exports to more than 50 countries

• Can get more profits

• Strictly control production time

• Cost is cheaper than CNC factory

• Complete production equipment

China's leading curtain wall aluminum profile manufacturer

Xingda curtain wall aluminum profile is a material used to construct building curtain wall systems. It is usually made of aluminum alloy through extrusion process and has the characteristics of light weight, high strength and corrosion resistance. Curtain wall aluminum profiles are widely used in the construction industry. They are used to support and fix the glass, plates or other exterior wall materials of the curtain wall, and also provide a certain degree of decoration.

Xingda can provide professional technical support and consulting services to help you solve problems encountered in design, material selection, production, etc., and provide professional advice.

Xingda Aluminum Profile Factory has certain advantages in the cost of curtain wall aluminum profiles, thus providing you with competitive prices.

Xingda Aluminum Profile Factory can provide high-quality curtain wall aluminum profiles, professional technical support, good after-sales service, and customization capabilities to meet your diverse needs. At the same time, Xingda also keeps pace with the times, pays attention to the development trends of the industry, and continuously improves its technical level and service level.

Xingda can provide customized curtain wall aluminum profiles and solutions according to your needs to meet the specific requirements of different projects. For example, in the curtain wall extruded aluminum profile industry, Xingda can customize and produce curtain wall aluminum profiles that meet your design drawings and specifications.

| Product name | Extruded aluminum profiles for curtain walls |

| Design style | modern |

| Project solving capabilities | 3D model design, overall project solution |

| Model | curtain wall |

| Packaging | standard packaging |

| Minimum order quantity | 300KG |

| Size | can be customized |

| Profile | 1. 6063-T5 high-quality insulated aluminum profile 2. 6063-T5 high-quality non-insulated aluminum profile |

| Port | Guangdong/Shenzhen |

| Delivery time | 22-30 days |

| Application | glass wall |

| Color | customized color |

| Surface treatment | powder coating, anodizing, wood grain, polishing, electrophoresis, etc. |

| Processing | extrusion, die casting, precision CNC machining, milling, etc. |

| OEM service | Yes |

Questions about extruded aluminum profiles for sliding windows

The prices of curtain wall aluminum profiles and industrial aluminum profiles are higher than those of ordinary door and window aluminum profiles.

Differences in thickness and structure lead to higher production difficulties and raw material scrap rates.

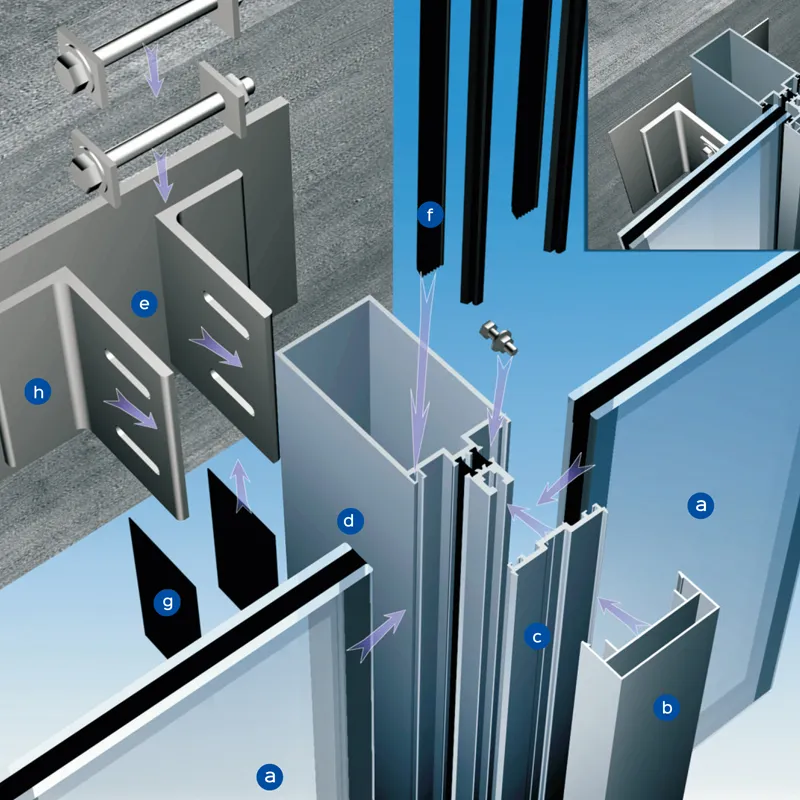

Step 1. Send us your detailed drawings or physical samples

Step 2. Our engineers will make mold design based on your drawings or samples.

Step 3. Detailed quotation of mold and product.

Step 4. Test product samples for confirmation.

Step 5. After the sample is confirmed, we can start mass production.

Step 1. Send us the authorization letter to use your brand name.

Step 2. We will design the packaging version logo according to your requirements.

Step 3. Version fee confirmation.

Step 4. OEM service for all your products.

A: Prices are based on the specific requirements of our buyers, so please provide information to help us quote you an accurate price.

1) Drawings, dimensions, quantity, model;

2) Frame color;

3) Glass type, thickness and color.

Welcome to send relevant drawings of curtain wall aluminum profiles to your email, and we will provide you with a quotation.”

Each piece comes with protective film and each bundle is wrapped with shrink film/kraft paper or as per your requirements. Champagne, dark bronze or according to your color swatch.

Professional curtain wall aluminum profile supplier

From casting, anodizing, powder spraying, electrophoresis, wood grain, etc. to one-stop production, the company is equipped with modern and advanced CNC processing lines to produce aluminum materials. Workers are well trained before starting work and provide a variety of transportation options to choose from. , we will provide you with the best prices and services!

Wall aluminum profile: The Ultimate Guide

Curtain wall aluminum profile is a kind of building material with excellent performance. It plays an important role in modern architecture. It not only provides structural support, but also has the function of beautiful decoration. At the same time, the plasticity and surface treatment diversity of aluminum profiles allow it to adapt to various architectural designs with different styles and requirements.

- 1.What are curtain wall aluminum profiles?

- 2.What are the types of curtain wall aluminum profiles?

- 3.What is the difference between exposed frame and hidden frame curtain wall aluminum profiles?

- 4.Which projects are suitable for exposed frame and hidden frame curtain wall aluminum profiles?

- 5.What are the profiles of curtain wall aluminum profiles?

- 6.What are the commonly used surface treatments for curtain wall aluminum profiles?

- 7.What issues should you pay attention to when purchasing curtain wall aluminum profiles?

- 8.In what areas are curtain wall aluminum profiles mainly used?

- 9.What are the related accessories for curtain walls?

What are curtain wall aluminum profiles?

Curtain wall aluminum profiles is a special aluminum component used to construct building curtain walls. It has the characteristics of light weight, high strength, corrosion resistance, and strong plasticity.

It plays an important role in modern architecture and is used for decoration, heat insulation, sound insulation, waterproofing and other functions. It also serves as the structural support part of the curtain wall system.

What are the types of curtain wall aluminum profiles?

Curtain wall aluminum profiles can be divided into the following main types according to their applications:

1.Universal curtain wall aluminum profiles: Universal curtain wall aluminum profiles are suitable for curtain wall systems in general buildings, including profiles of various shapes, such as square tubes, circular tubes, beams, columns, etc., and are commonly used in residential and commercial buildings, etc.

2.Insulated curtain wall aluminum profiles: Insulated curtain wall aluminum profiles use special structural design and thermal insulation materials to improve the thermal insulation performance of the curtain wall system for projects with high energy-saving and thermal insulation requirements. They are common in high-standard energy-saving buildings.

3.Structural curtain wall aluminum profiles: Structural curtain wall aluminum profiles are mainly used in construction projects that can withstand large wind loads and external pressures. They have high strength and stability and are usually used for the main structure of high-rise building curtain wall.

4.Photovoltaic curtain wall aluminum profiles: Photovoltaic curtain wall aluminum profiles are designed to adapt to solar photovoltaic curtain wall projects. They have structural characteristics that are suitable for solar panel installation and can achieve effective utilization of solar energy.

5.Tempered glass curtain wall aluminum profiles: Tempered glass curtain wall aluminum profiles are suitable for curtain wall projects that require the installation of large areas of tempered glass. They have special structural designs to ensure the safety of the glass.

6.Canopy-type curtain wall aluminum profiles: Canopy-type curtain wall aluminum profiles are mainly used for canopies or sunshade facilities outside buildings, and have good waterproof and sunshade functions.

7.Decorative curtain wall aluminum profiles: Decorative curtain wall aluminum profiles are used to enhance the decorative nature of the curtain wall. They can use various surface treatments and designs to give them special visual effects.

8.Fire-resistant curtain wall aluminum profiles: Fire-resistant curtain wall aluminum profiles have fire-resistant properties and are often used in construction projects that require high fire-resistant performance, such as high-rise buildings, public places, etc.

According to the specific construction project needs, the appropriate type of curtain wall aluminum profiles can be selected to meet the corresponding functions and requirements.

What is the difference between exposed frame and hidden frame curtain wall aluminum profiles?

Exposed frame curtain wall aluminum profiles and hidden frame curtain wall aluminum profiles are two types of aluminum profiles commonly used in building curtain wall systems. Their differences mainly lie in the installation structure and appearance:

1.Installation structure:

• Exposed frame curtain wall aluminum profiles: When the aluminum profiles of the exposed frame curtain wall are installed, the outer surface of the aluminum can be directly seen, forming an obvious frame structure, and the aluminum materials, connectors and other components of the curtain wall are visible from the outside.

• Hidden frame curtain wall aluminum profiles: When the aluminum profiles of the hidden frame curtain wall are installed, the outer surface of the aluminum is almost invisible, and most of the aluminum is hidden inside the curtain wall, forming an effect where there is almost no visible frame in appearance.

2.Aesthetics:

• Exposed frame curtain wall aluminum profiles: Since the aluminum frame is visible on the outside, the exposed frame curtain wall has an obvious frame structure, which is visually decorative and artistic.

• Hidden frame curtain wall aluminum profiles: Since there is almost no visible frame structure on the outside, the hidden frame curtain wall visually presents a simple, pure and neat effect, and the appearance is more modern and grand.

3.Construction difficulty:

• Exposed frame curtain wall aluminum profiles: The installation of exposed frame curtain wall is relatively simple, the construction difficulty is low, and it is suitable for some small and medium-sized projects.

• Hidden frame curtain wall aluminum profiles: The installation requirements of hidden frame curtain walls are relatively high, requiring high-level construction technology and precise processing technology. The construction is relatively difficult and suitable for some high-end projects or special design requirements.

In general, the biggest difference between exposed frame curtain walls and hidden frame curtain walls is the difference in appearance after installation. The aluminum frame of the exposed frame curtain wall is visible from the outside, while the obvious frame structure of the hidden frame curtain wall is almost invisible. The choice of which type of curtain wall to use depends on the design requirements of the specific project as well as budgetary considerations.

Which projects are suitable for exposed frame and hidden frame curtain wall aluminum profiles?

There are some differences in the design and construction of exposed frame curtain wall aluminum profiles and hidden frame curtain wall aluminum profiles, so they are suitable for different types of projects:

1.Exposed frame curtain wall aluminum profiles are suitable for:

• Commercial buildings: such as shopping malls, office buildings, etc. The appearance of the exposed frame curtain wall is relatively traditional, which can meet the decoration needs of commercial buildings, and the installation is relatively simple, making it suitable for some moderate-sized commercial projects.

• Mid- and low-rise buildings: For buildings that are not too tall, exposed frame curtain walls can often provide sufficient structural strength and are relatively easy to construct. They are suitable for multi-story residential buildings, etc.

• Buildings with high decorative requirements: Because the appearance of the exposed frame curtain wall relatively highlights the frame structure, it is suitable for projects that need to emphasize decoration in the facade design.

• Projects with limited budgets: Compared with hidden frame curtain walls, the construction difficulty and cost of exposed frame curtain walls are lower, and they are suitable for some projects with limited budgets.

2.Hidden frame curtain wall aluminum profiles are suitable for:

• High-end buildings: The hidden frame curtain wall has a simple and elegant appearance, which can reflect the quality and modernity of high-end buildings and is suitable for high-end commercial buildings, high-end residential projects and other projects.

• Buildings with high requirements on appearance: Since the appearance of hidden frame curtain wall is extremely pure, it is suitable for some building projects that pursue simple, modern and fashionable design styles.

• High-rise buildings: The structural design and connection method of hidden frame curtain walls make them have strong wind pressure resistance and are suitable for high-rise buildings.

• Buildings with special design requirements: such as cultural buildings, art museums, etc. that have unique requirements for exterior wall design.

In general, exposed frame curtain walls and hidden frame curtain walls each have their own applicable scenarios, and the specific choice depends on factors such as the project’s design concept, budget, building type, and the climate of the region.

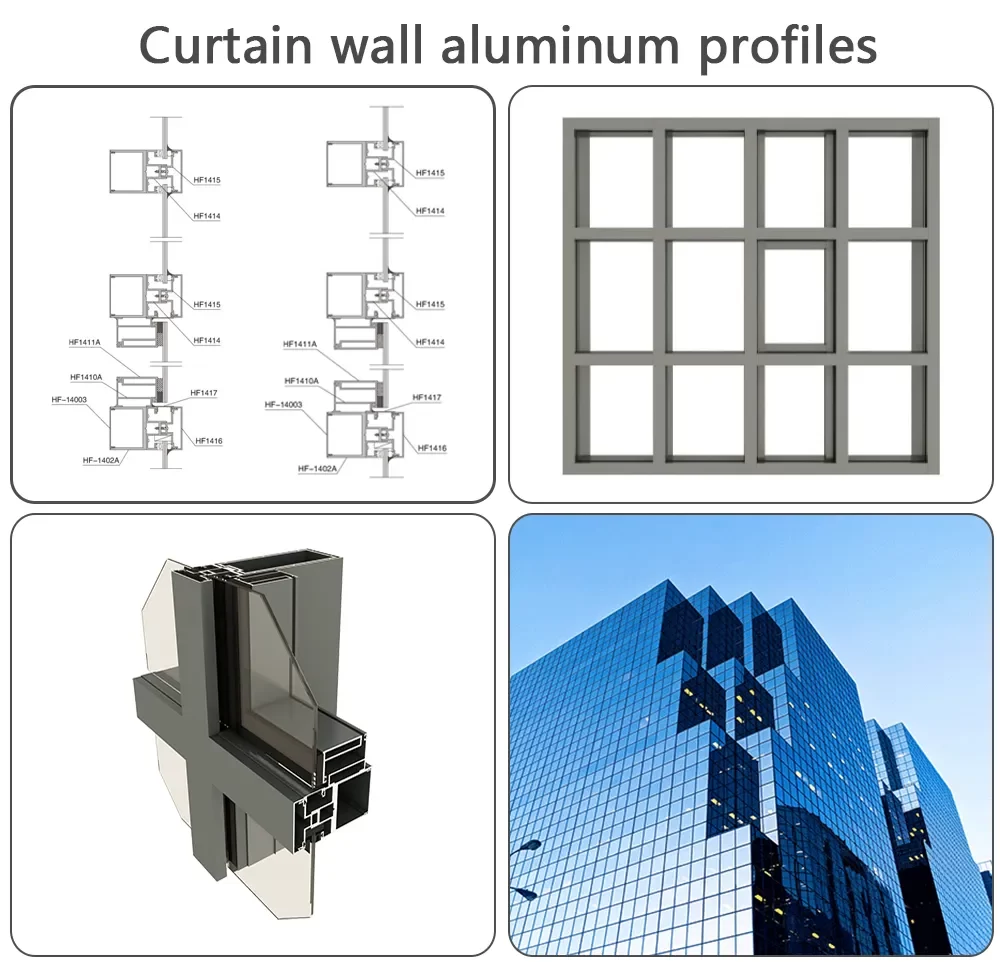

What are the profiles of curtain wall aluminum profiles?

Curtain wall aluminum profiles are an aluminum material used to build curtain wall systems, usually available in a variety of shapes and specifications to meet different design and construction needs. The following are some common curtain wall aluminum profiles:

• Square profile: It has a rectangular or square cross-section and is often used in the frames, beams, columns and other parts of curtain walls.

• Round profile: It has a circular cross-section and is often used in curved parts of curtain walls or when bending is required.

• Sector timber: has a sector-shaped cross-section and is usually used in specially designed parts of curtain walls, such as round windows or arched structures.

• T profile: The cross-section is “T” shaped, usually used for the connection and support of curtain walls.

• H profile: The cross-section is in the shape of “H” and is usually used for beams of curtain walls or parts that need to bear larger loads.

• Z profile: The cross section is in the shape of “Z” and is usually used for the connection and support of curtain walls.

• U profile: The cross section is in the shape of “U” and is usually used for the connection and support of curtain walls.

• Angle iron profile: “L” shaped cross section, usually used for corner connection or support of curtain walls.

• Special-shaped materials: In addition to the common shapes mentioned above, Xingda can also customize various special-shaped materials according to specific design needs to meet special design requirements.

What are the commonly used surface treatments for curtain wall aluminum profiles?

Commonly used surface treatment methods for curtain wall aluminum profiles include anodizing, spraying and electrophoretic coating, of which anodizing is one of the commonly used surface treatment methods.

Anodizing is a surface treatment process that improves corrosion resistance and decorative properties by forming an oxide film on the surface of aluminum profiles. This oxide film can improve the hardness and wear resistance of aluminum, and can also change its appearance and color to give it a better decorative effect.

In addition to anodizing, spraying and electrophoretic coating are also commonly used surface treatment methods for curtain wall aluminum profiles:

• Spraying: Use spraying equipment to evenly spray the paint on the surface of the aluminum profile to form a protective film, which can improve its corrosion resistance and aesthetics. Spray coating is often used to achieve some special requirements for colors and effects.

• Electrophoretic coating: Soak aluminum profiles in paint containing pigments, and use current to control the deposition of pigments on the aluminum surface to form a uniform coating with good coating uniformity and adhesion.

The choice of surface treatment should be based on the requirements and design style of your specific project. Anodizing is usually used in modern-style buildings with metallic textures, while spray coating and electrophoretic coating can provide more color and effect choices and are suitable for more diverse design needs.

What issues should you pay attention to when purchasing curtain wall aluminum profiles?

When purchasing curtain wall aluminum profiles, you need to pay attention to the following important issues:

1.Material selection: Curtain wall aluminum profiles are usually made of aluminum alloy, but different aluminum alloy materials have different characteristics, such as strength, corrosion resistance, etc. Selecting the appropriate aluminum alloy material can be determined based on specific project needs and environmental conditions.

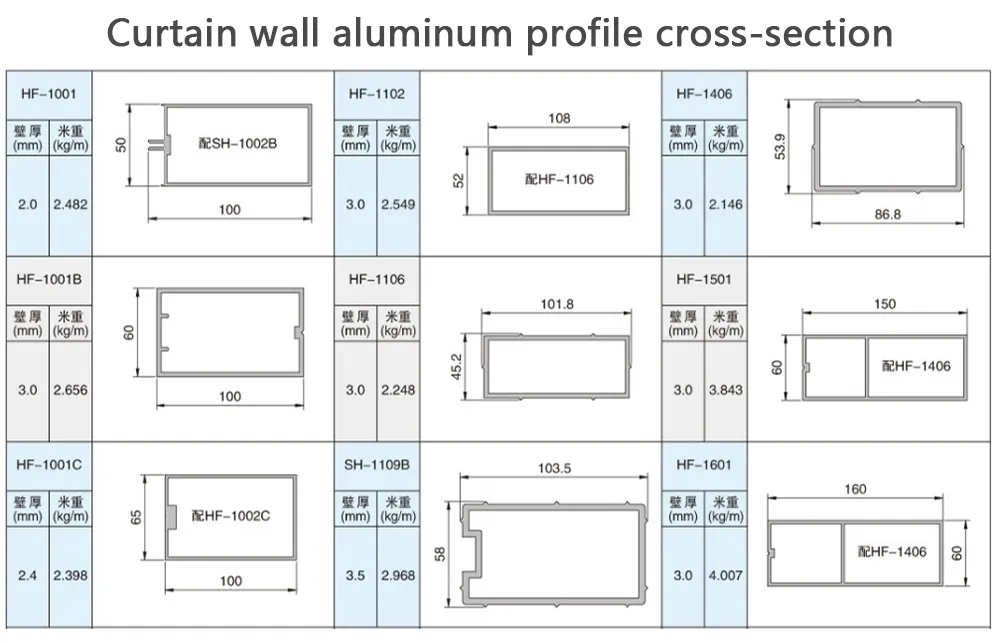

2.Specifications and dimensions: According to the specific design plan, aluminum profiles that meet the size requirements need to be selected. This includes parameters such as the cross-sectional shape and length of the profile.

3.Surface treatment: Curtain wall aluminum profiles usually require surface treatment, such as anodizing, spraying, etc., to improve their corrosion resistance and appearance. Choose the appropriate surface treatment based on project needs.

4.Sectional design of profiles: Different section designs of curtain wall profiles can meet different functional requirements, such as heat insulation, structural support, etc. Choose the appropriate sectional design based on your project needs.

5.Manufacturer reputation: Choose an aluminum profiles manufacturer with a good reputation to ensure product quality and after-sales service.

6.Compliance certification: Ensure that the purchased curtain wall aluminum profiles comply with the building material standards and certification requirements of relevant countries or regions, such as CE certification, ISO certification, etc.

7.Price and cost: Based on the project budget and quality requirements, reasonably evaluate the price of curtain wall aluminum profiles, and take into account subsequent installation, maintenance and other costs.

8.Accessories and connectors: In addition to the aluminum profiles itself, supporting connectors, sealing materials, etc. also need to be considered to ensure the integrity and stability of the entire curtain wall system.

9.Logistics and transportation: Considering the size and weight of aluminum profiles, logistics and transportation arrangements need to be properly planned to ensure that the product is not damaged during transportation.

10.After-sales service: Understand the after-sales service policy provided by the manufacturer, including warranty period, repair, replacement, etc., to ensure that problems during use can be solved in a timely manner.

To sum up, choosing the right curtain wall aluminum profiles requires full consideration of the specific needs of the project, quality requirements, and the reputation and after-sales service of the manufacturer to ensure that your project proceeds smoothly and achieves the expected results.

What are the main applications of curtain wall aluminum profiles?

Curtain wall aluminum profiles are mainly used in building curtain wall systems, which is its most common application field. Building curtain walls refer to non-load-bearing components installed on the exterior facade of buildings. They are usually composed of aluminum alloy profiles, glass, and other materials. They mainly serve the functions of decoration, heat insulation, sound insulation, and waterproofing.

The following are the main applications of curtain wall aluminum profiles:

1.Commercial buildings: including office buildings, shopping malls, hotels and other commercial complexes. In these buildings, curtain walls are not only beautiful, but can also enhance the quality and image of the overall building.

2.Residential buildings: Residential projects such as high-rise apartments and residential communities also often use curtain wall aluminum profiles. They can improve the appearance of the building and increase living comfort.

3.Cultural buildings: including museums, art galleries, theaters and other cultural facilities. In these buildings, curtain walls not only play the role of protecting cultural relics and artworks inside the building, but can also become an artistic element of the building itself.

4.Educational buildings: Educational institutions such as schools and universities also use curtain walls to enhance the overall image of educational venues.

5.Medical buildings: Medical institutions such as hospitals and clinics will also use curtain walls to provide a refreshing and bright medical environment.

6.Sports buildings: Sports facilities such as stadiums and gymnasiums also need curtain walls to ensure the audience experience of internal events.

7.Industrial buildings: Some special industrial buildings, such as R&D centers, high-tech factories, etc., may also use curtain wall aluminum profiles to meet their special construction needs.

In general, curtain wall aluminum profiles are widely used in modern buildings. Through appropriate design and material selection, the appearance, function and performance of the building can be comprehensively improved.

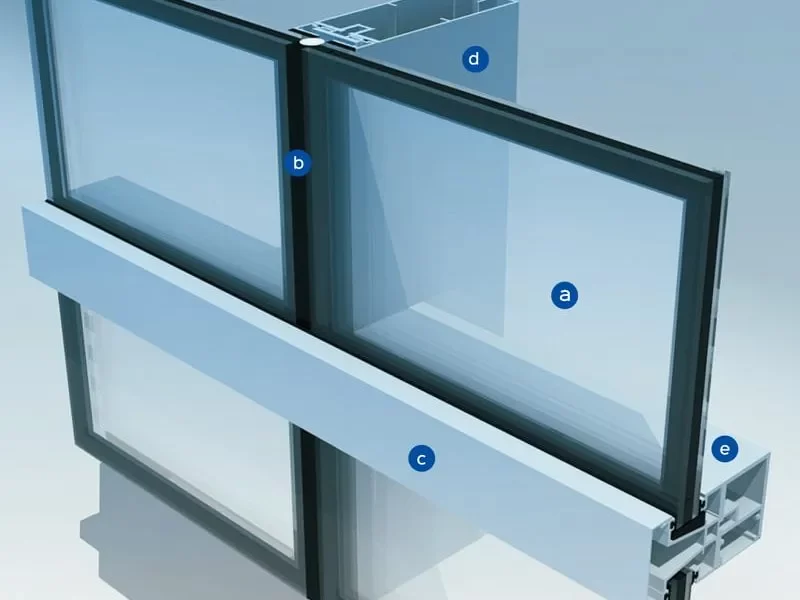

What are the related accessories for curtain walls?

The following are some common related accessories for curtain walls:

1.Sealing material: used to fill gaps and joints in the curtain wall structure to ensure the waterproof, windproof and other properties of the curtain wall.

2.Pad: installed between the aluminum profile of the curtain wall and the glass to support and protect the glass.

3.Connectors: used to connect aluminum profiles of curtain walls to ensure the stability and integrity of the curtain wall structure.

4.Guard plate: used to protect the curtain wall structure and aluminum profile surface from external damage.

5.Waterproof/Windproof Strips: Installed at the joints of curtain wall aluminum profiles for waterproofing, windproofing and sound insulation.

6.Adhesive strips/sealing strips: Used to fill gaps in the curtain wall structure to provide waterproofing, windproofing, and sound insulation.

7.Hanging parts: used to fix the curtain wall structure and connect the curtain wall to the main structure of the building.

8.Bearings: Rotating bearings used in openings of curtain wall structures, such as windows or curtain walls.

9.Tie rods: used to provide additional support and stability to enhance the load-bearing capacity of the curtain wall structure.

10.Expansion bolts: Metal members used to connect curtain wall structures, usually for concrete or brick walls.

11.Air duct: used for ventilation or exhaust in the curtain wall system to ensure ventilation and air circulation inside the building.

12.Laminated glass connectors: Metal frames and support systems used to connect laminated glass.