Aluminum Extrusion Handle Supplier

- OEM aluminum extrusion handles

- Customized aluminum extrusion handles

- Small batch aluminum extrusion handle supply

- Aluminum extrusion cabinet handle manufacturer

Xingda: Design and manufacture of aluminum extruded handles

| Place of Origin | Guangdong, China |

| Temper | T5 |

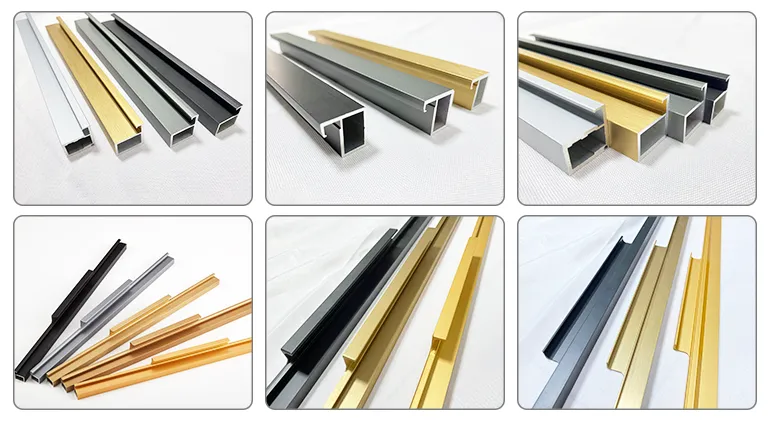

| Application | kitchen cabinet |

| Alloy Or Not | Is Alloy |

| Processing Service | Punching, Cutting |

| Surface treatment | Anodized |

| Material & Temper | 6063-T5 Aluminum Extruded Alloy |

| Payment term | T/T;L/C |

| OEM Service | OEM Accept |

| Product Name | Modern minimalist extruded aluminum cabinet furniture handles |

| Thickness | 1.8/2.2mm |

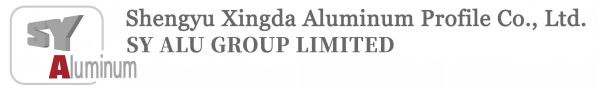

| Color | Grey ,coffe, gold, black,matt black,brushed gold bronze,white |

| Length | 1-3m/pcs(Customized) |

| Sample | Freely |

| Delivery Time | Normally in 7 days if in stock |

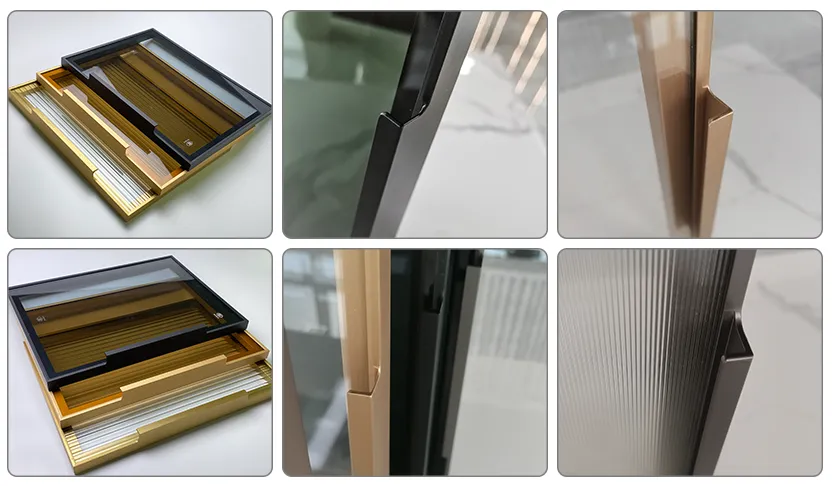

Xingda Aluminum Profiles has a large stock of extruded aluminum handles, which can provide you with instant delivery services to ensure fast delivery. This advantage of extruded aluminum handles in stock means that you do not need to wait for the production cycle, and can quickly meet market demand and sell in time, thereby improving your operational efficiency and market responsiveness.

Xingda’s extruded aluminum handles are made of 6063 aluminum alloy profiles. 6063 aluminum alloy is very suitable for manufacturing various high-quality aluminum extrusion products, including furniture handles, door and window aluminum profiles, industrial aluminum profiles, etc. due to its excellent mechanical properties, high corrosion resistance and good machinability.

In markets such as Thailand, Malaysia, the Philippines and Singapore, popular colors for extruded aluminum handles include modern black, classic and versatile silver, fresh and simple white, high-end gold and brushed stainless steel with a metallic texture. These colors of extruded aluminum handles are popular in these Southeast Asian countries because they can adapt to different decoration styles and customer needs.

As a manufacturer of OEM extruded aluminum handles, Xingda provides one-stop service from design to delivery to meet your needs in all aspects. We focus on high-quality production, using high-quality 6063 aluminum alloy, through precision extrusion process and strict quality control to ensure the strength, durability and aesthetics of extruded aluminum handles. Our services cover the design, sample making, small and large batch production, packaging and logistics of extruded aluminum handles, and are committed to providing you with efficient, flexible and customized solutions.

Customized extruded aluminum handle production covers a full range of services from preliminary design to final delivery. Xingda Aluminum Profiles can provide personalized design according to your needs, including customization of extruded aluminum handles in terms of size, shape, surface treatment, color, etc., and perform mechanical analysis and ergonomic optimization. In addition, we can also provide sample production, small batch production, large batch production, and packaging and logistics services for extruded aluminum handles to ensure that the extruded aluminum handles meet your requirements precisely and are delivered on time.

What are the extrusion processes for extruded aluminum handles? Which extruded aluminum handles will use these processes?

The extrusion processes for extruded aluminum handles usually include the following:

1. Direct extrusion:

Process description: The most common aluminum extrusion process, in which the aluminum material is pushed into a die by an extruder to form the desired handle shape. Extruded aluminum handles of different sizes and shapes can be produced through a series of extrusion dies and extruders.

Application type: straight aluminum handles, T-shaped aluminum handles, U-shaped aluminum handles.

2. Indirect extrusion:

Process description: Also known as indirect extrusion forming, this method requires the use of auxiliary tools such as curved dies or steel cores compared to direct extrusion. The aluminum material is extruded into the desired shape after a series of auxiliary tools.

Application type: complex shape aluminum handles.

3. Deep drawing extrusion:

Process description: The aluminum sheet or strip is deep drawn in a die to form the entire or partial shape of the aluminum handle. This method is usually used to produce more complex aluminum handle designs, requiring a high degree of mold precision and processing technology.

Application type: complex shape aluminum handles.

4. Curve extrusion:

Process description: The aluminum material is bent or turned in the extruder so that it forms the curved part of the aluminum handle along a predetermined curved path. This method is suitable for aluminum handle designs that require bending or arcs.

Application type: bent aluminum handles, curved aluminum handles.

5. Shear extrusion:

Process description: The aluminum material is sheared into the desired shape and then processed into the design of the aluminum handle through an extruder. This method is usually used to produce smaller handles or designs that require specific shapes.

Application type: small size or specific shape aluminum handles.

Xingda Aluminum Profile’s aluminum handle extrusion process has its specific application scenarios and advantages and disadvantages. The selection of a suitable aluminum extrusion process depends on the aluminum handle design, material properties, and production requirements. Different types of aluminum handles may require different processes to meet their design requirements, and sometimes a combination of multiple processes are used to achieve specific shapes and functions. Contact us for a catalog of aluminum handles and quotes